VIFOR KGM 4400

VIFOR KGM 4400

Basis

Gasket material based on Aramid fibre & organic fibre with NBR binder.

Application

Suitable for oils, fuels, lubricants, alcohols, gases, hydrocarbons, steam, water, cooling liquids, most diluted acids and alkalies for medium stress conditions.

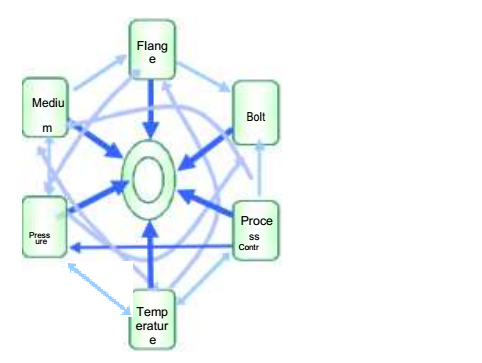

The suitability of a gasket material for an application is dependent upon a multiplicity of factors as shown in the above digram. Max. temperature and pressure values can not define the suitability for application. It is always advisable to consider these factors when selecting a material for a given application.

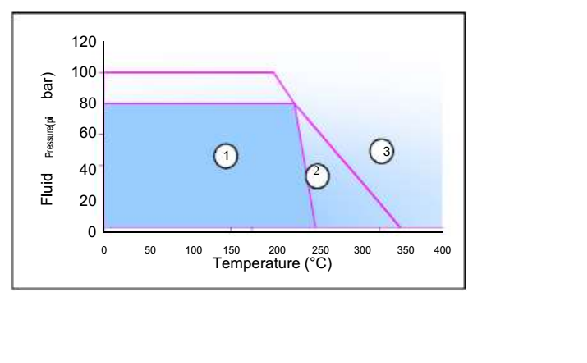

1 This area refer , the gasket material is normally suitable subject to chemical compatibility.

2 This area refer, the gasket material may be suitable but a technical support is recommended.

3 This area refer, do not install the gasket without technical evaluation.

Dimensions of the standard sheets :

Standard sheet sizes :1500 X1500 mm,1500 X2250mm, 1500 X4500 mm ,1500 X1000 mm,1000X1000mm 1500 X4000 mm, 1500 X2000 mm, 1300 X3900 mm, 1270 X1270 mm, 2100 X 3000 mm, 1500 X 3000 mm.

Finish : Green , Biue,Grey,White

(other Colour on Customer requirement).

ASTM F 104 Line Call out : F 712911 E12 A9 B5 M5

Technical data

All data are typical values and refer to sheet thickness of 2.0 mm

| Test method | Specified | Unit | |

Max. Peak Temperature |

| 350 | °C |

|

Max. Operating Temperature |

| 250 | °C |

|

Max. Operating Pressure |

| 100 | bar |

|

Density | ASTM F 1315 | 1.60 - 1.90 | g/cm³ |

|

Compressibility | ASTM F 36 J | 7 -17 | % |

|

Recovery | ASTM F 36 J | ≥ 40 | % |

|

Tensile Strength | ASTM F 152 | ≥ 10.5 | N/mm² |

|

Creep Relaxation | ASTM F 38 B | ≤ 30 | % |

|

Stress Relaxation (16h 175° C) | DIN 52913 | ≥ 22 | N/mm² |

|

Gas Sealability | ASTM F 37 B | < 1.0 | ml/ hour. |

|

ASTM oil no.3 (5h, 150°C) | ASTM F 146 |

|

|

|

Thickness Increase |

| ≤ 10 | % |

|

Weight Increase |

| ≤ 10 | % |

|

ASTM Fuel B (5h, 23°C) | ASTM F 146 |

|

|

|

Thickness Increase |

| ≤ 10 | % |

|

Weight Increase |

| ≤ 10 | % |

|

Water (5h, 100°C) | ASTM F 146 |

|

|

|

Thickness Increase |

| ≤ 10 | % |

|

Weight Increase |

| ≤ 10 | % |

|

All information and recommendations given in this brochure are correct to the best of our knowledge . However , in view of the wide variety of possible installation and operating conditions one cannot draw the finel conculusion in all application cases regarding the behaviour in a gasket joint . Therefore , information can only serve as a guideline. |

| |||