VIFOR KGM 1000

VIFOR KGM 1000

TECHNICAL DATA SHEET

Material Composition:

Chrysotile non asbestos , Natural Rubber & Nitrile Butadiene Rubber with 16 mesh G. I. wire reinforced.

General properties and applications :

To seal off alcohols, water, air, steam, oils, fuels, etc. Thic grade is specialli suitable for internal combustion engines, compressors, pipe - lines and several other industrial applications under medium stress conditions.

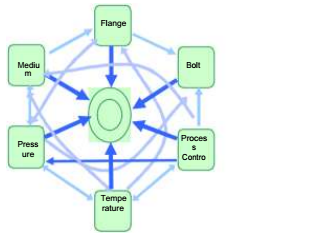

Factors affecting on the gasket

The suitability of a gasket material for an application is dependent upon a multiplicity of factors as shown in the above digram. Max. temperature and pressure values can not define the suitability for application. It is always advisable to consider these factors when selecting a material for a given application .

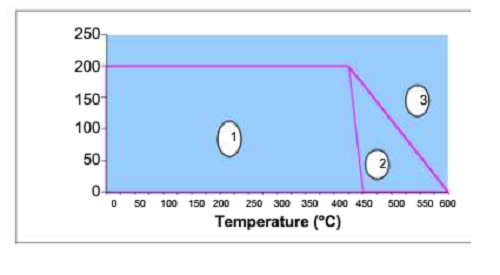

Areas of application

1 This area refer , the gasket material is normally suitable subject to chemical compatibility.

2 This area refer, the gasket material may be suitable but a technical support is recommended.

3 This area refer, do not install the gasket without technical evaluation.

DIMENSIONS OF STANDARD SHEETS :

Standard sheet sizes :1500 X1500 mm,1500 X2250mm, 1500 X4500 mm ,1500 X1000 mm,1000X1000mm 1500 X4000 mm, 1500 X2000 mm, 1300 X3900 mm, 1270 X1270 mm, 2100 X 3000 mm, 1500 X 3000 mm.

FINISH : Grey/Graphite ,(other Colour on Customer requirement).

IS 2712 : 1998

Technical data

All data are typical values and refer to sheet thickness of 1.5 mm

| Test method | Specified Value | Unit |

Max. Operating Temperature |

| 600 | °C |

Max. Operating Pressure |

| 200 | bar |

Density | ASTM F 1315 | 1.8 -2.30 | g/cm³ |

Compressibility | ASTM F 36 A | 6-14 | % |

Recovery | ASTM F 36 A | ≥ 40.0 | % |

Tensile Strength | ASTM F 152 | ≥ 26.0 | N/mm² |

Stress Relaxation (16h, 300⁰C ) | DIN 52913 | ≥ 25.0 | N/mm² |

Loss on ignition | ASTM F 495 | ≤ 26 | % |

ASTM oil no.3 (5h, 150°C) | ASTM F 146 |

|

|

Thickness increase |

| ≤ 25 | % |

Weight increase |

| ≤ 20 | % |

ASTM Fuel B (5h, 23°C) | ASTM F 146 | - |

|

Thickness increase |

| ≤ 20 | % |

Weight increase |

| ≤ 20 | % |

Weight increase in Water (48h,3°C) | ASTM F 146 | ≤ 10.0 | % |

Flexibility | ASTM F 147 B | No Cracks | -- |

All information and recommendations given in this brochure are correct to the best of our knowledge. However, in view of the wide varity of possible installation and operating conditions one cannot draw the final conclusion in all application cases regarding the behaviour in a gasket joint. Therefore, information can only serve as a guideline.